Expert engineers, advanced tools

SIMERA Technology Group (SIMERA) is a mechanical

engineering development company built around core capabilities of

advanced structural design and simulation services. Founded in 2010, the

company has 18 permanent employees representing more than 130 years of

engineering experience.

SIMERA’s clients include customers in government, research,

industrial equipment, and consumer product industry sectors. To excel in

these domains, SIMERA employs highly-skilled, experienced and

passionate engineers. Equally important, SIMERA uses advanced,

best-in-class engineering and product lifecycle management (PLM)

solutions to maintain a competitive edge.

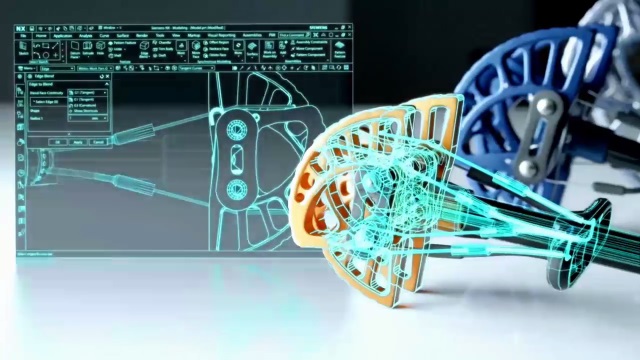

PLM solutions from Siemens PLM Software help SIMERA’s engineers work

with precision, efficiency and creativity. From design through to

simulation and PLM, the cross-functional, comprehensive capability of

Siemens PLM Software tools make this possible. SIMERA appreciates the

collaboration and rapid design iteration capabilities of the solutions,

which aid the creative thinking of development teams.

The engineering and PLM solutions help orchestrate projects and track

changes in a completely traceable manner, giving design leads immediate

insight into the rationale and direction of design iterations.

A unified design and simulation solution

SIMERA formerly used different computer-aided design

(CAD) and finite element analysis (FEA) software tools. The tools in

themselves were productive, but SIMERA engineers had to transfer

information manually, handing data “over the wall” between the design

and simulation domains. The manual information handoffs were not

efficient and sometimes lead to versioning errors or simulation model

errors.

Implementing NX™

and Simcenter™ software was a natural step for SIMERA, as it provided a

unified CAD and simulation solution that better suited the company’s

quality, control and efficiency requirements. NX and Simcenter 3D, which

is also built on the NX platform, enable SIMERA to easily and quickly

move back and forth during the design and simulation cycle. Simulation

engineers can directly or collaboratively request model changes, and

validate those changes immediately. The added productivity of the

unified solution quickly justified the investment.

Improving control of the design processes

SIMERA also uses Teamcenter® software to improve

control over design processes. As is typical in small-to-medium

enterprises, SIMERA frequently relies on the expertise of key team

members to track and optimize requirements, link documents and manage

projects. This ad hoc approach has many limitations, especially in

projects involving extended resources, complex requirements and critical

non-compliance implications.

The company realized that PLM was essential for improving design

management, particularly in projects with an extended team of

stakeholders, larger design teams, complex requirements and strict

contractual obligations for execution. After an evaluation of available

PLM tools, SIMERA decided on Teamcenter because its capabilities spanned

a broad spectrum of the engineering processes. Other important criteria

included seamless integration with the NX CAD software and scalability

that would enable the system to grow with the company’s expansion. The

capabilities of Teamcenter for controlling product data with versioning

and traceability and for managing the design process were crucial in

fulfilling SIMERA’s requirements.

Excellent local support

The availability of local support for the solutions was also an important factor in SIMERA’s decision. The company relies on ESTEQ,

a Siemens PLM Software channel partner, for strategic consulting,

in-house training and system delivery, deployment and support. As the

largest provider of engineering simulation solutions in South Africa,

ESTEQ brought experience and expertise that were perfectly aligned with

SIMERA’s own core competencies. “Having excellent local support gives us

the confidence to tackle demanding tasks,” says Johann du Toit, chief

executive officer, SIMERA.

Pushing simulation to the limits

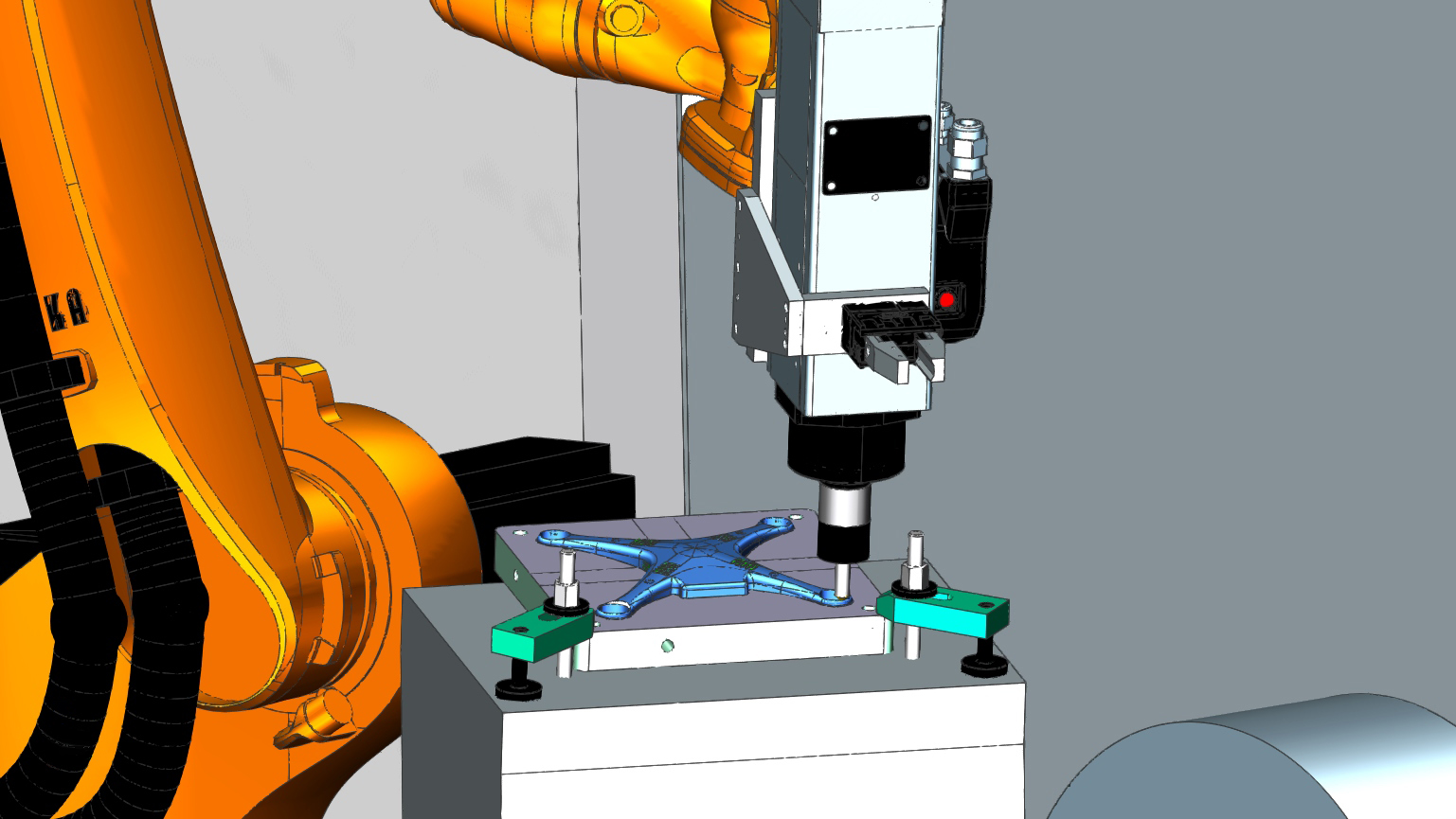

SIMERA engineers apply the unified NX and Simcenter

design and simulation solution to optimize the performance of precision

spaceborne imaging systems.

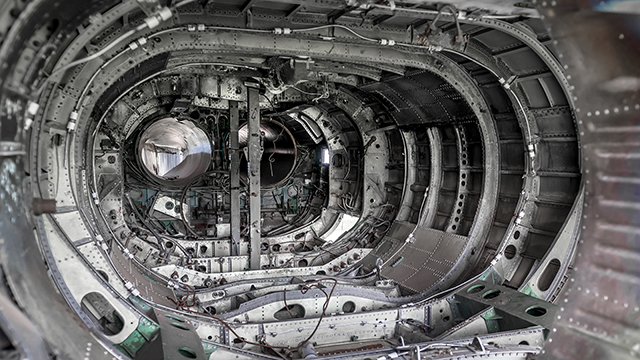

Satellite imagers have demanding requirements for controlling optical

surface deformations that could compromise image quality. Typically, a

10 micron rigid body movement of an optical surface can lead to an image

plane movement of 100 microns or more, and focus retention must be kept

within 20 microns or less. Likewise – but far more stringent –

deformations of optical surfaces themselves must be kept in check to a

tenth or more of the wavelength being reflected or refracted, which for

visible spectrum imagers starts at 450 nanometers. To put this in

perspective, a typical human hair thickness is about 200 times this

value. Clearly, error contributors should be fully understood and

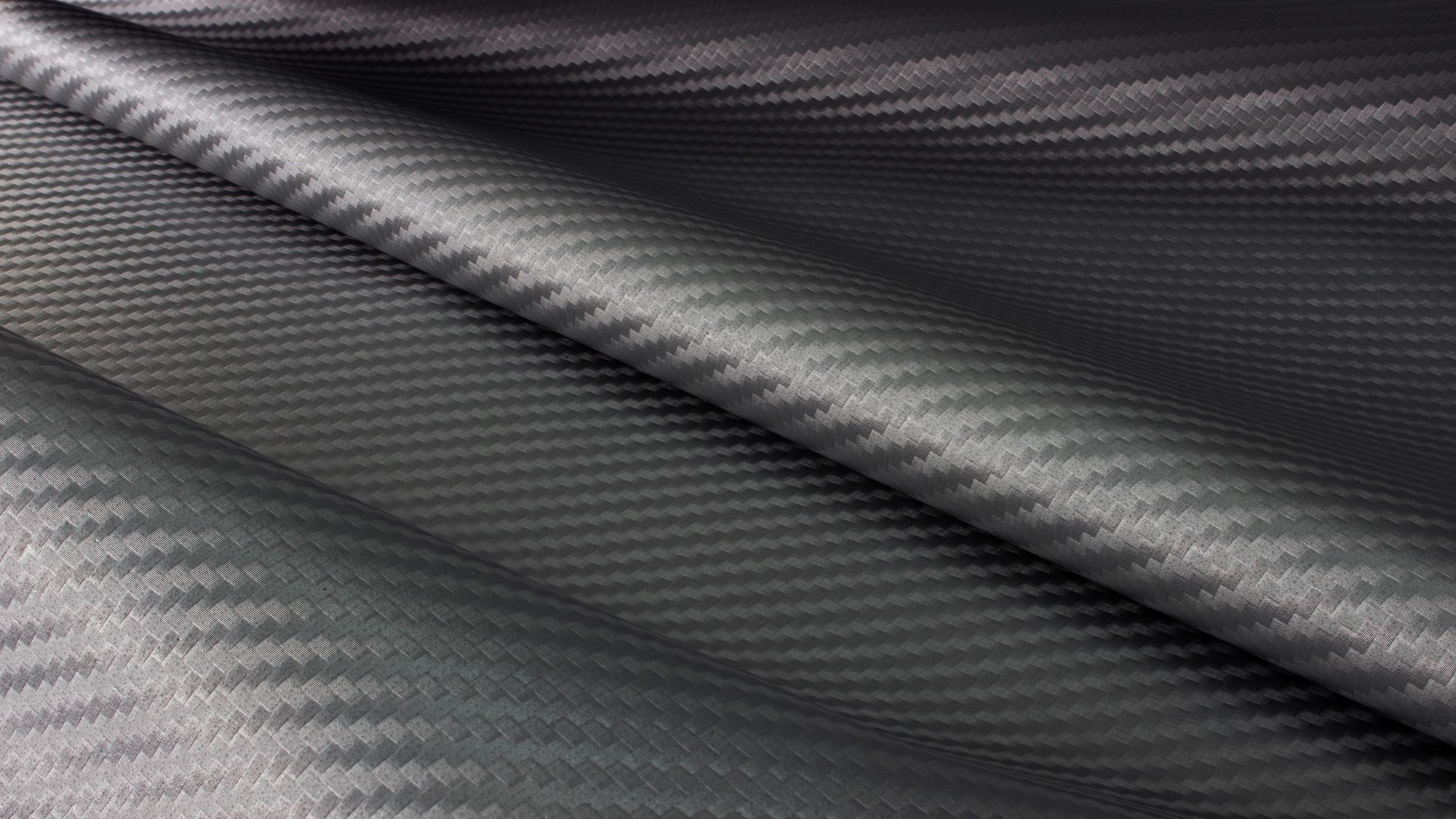

analyzed to ensure successful operation. Furthermore, for flight

systems, structural components are usually made from carbon-fiber

reinforced polymer (CFRP) materials, whose behavior under fluctuating

thermal and moisture loss conditions are not always apparent due to

non-symmetric laminates and their geometries.

SIMERA’s challenge is to optimize component stiffness, thermal

expansion, and moisture expansion, taking into account the harsh

vibration of the launch, the vacuum and the constant thermal cycling of

the space environment. Simulating the component’s behavior requires a

multitude of scenarios involving multiple thermal and moisture-loss load

cases, as well as multiple options for the fiber directions in the

composite material layups.

The integrated design and simulation tools of NX and Simcenter 3D

help accelerate the extensive investigation. “Having an integrated

CAD-to-simulation environment greatly enhances the efficiency of design

iterations,” says Hennie Roodt, lead engineer at SIMERA. The system’s

ease of use was also beneficial to the engineers. “The Simcenter 3D

graphical user interface is intuitive and follows practical simulation

execution logic,” says Marius Cronje, lead engineer.

After many design and simulation cycles, SIMERA engineers were able

to optimize the design, improving the rigidity of the components while

minimizing the expansions due to temperature cycles and moisture losses.

SIMERA estimates that the all-inclusive tools of Simcenter make the

process three- to five-times more efficient. In practice, this means

that many more design options and scenarios can be investigated to

ensure optimal solutions. “Having the capability to quickly and

accurately investigate precise structural behavior, exposed to a

multitude of operational environments, greatly reduces our product

development risks,” adds Du Toit

Systems engineering with Teamcenter

The systems engineering capabilities of Teamcenter are

also crucial to SIMERA’s success with satellite imager projects. To

initiate projects, SIMERA engineers use Teamcenter to capture and

analyze the technical and performance requirements of the imaging system

as well as to define measurements and verification and validation

procedures.

The Teamcenter requirements management tools make the requirements

visible to everyone in the development team, which enables SIMERA to

allocate them to physical components and to continuously trace, verify

and maintain them. Requirements are also fully integrated with the

design tools of NX, so designers using NX could view requirements

information when creating or modifying component models. With NX

requirements validation tools, SIMERA engineers continuously check

designs for compliance.

looslib (Mechanical)

If your company wants to seriously evaluate UG, contact them and they

may loan you a copy for 30-60 days.

“Wildfires are dangerous, hard to control, and economically catastrophic.”

Ben Loosli

CAD/CAM System Analyst

Ingersoll-Rand

Jason 123 (Mechanical)

for uses Solidworks, and it is sufficient for our needs. However, due

to company turmoil (layoffs, instability, no warm fuzzy anymore), I’ve

decided to look else for work. One highly regarded company in my area

uses UG and I want get some familarity to help get my foot in the door.

mjcole (Mechanical)

I’d try

to emphasize your previous experience with other software and ability to

learn quickly. Where I work now I got the position by convincing the

company that I’d be able to pick up UG quickly with my Pro/E and Catia

background.

It took me a few weeks to learn the basics and a few

months later I was modeling an Airfoil. UG can be frustrating at times

but after making some mistakes you’ll be able to avoid them in the

future. UG has a nice Training System called CAST Computer Assisted Self

Teach that can help you become comfortable with the software.

This

forum also has a lot of good postings and helpful engineers that can

help you find answers to common questions. I know it helped me out when I

first started learning UG.

Good Luck in your Job search.

Michael