LESSON 3270 & 3271 Mon 9 & Tue 10 Feb 2020

from

Dr B.R.Ambedkar thundered “Main Bharat Baudhmay karunga.” (I will make India Buddhist)

All Aboriginal Awakened Societies Thunder ” Hum Prapanch Prabuddha Bharatmay karunge.” (We will make world Prabuddha Prapanch)

online step by step guide to start integrated product design and

manufacture of commercial solar airplanes and to organise pilgrimage

flights

Connectivity is at the heart of Facebook’s work to bring the world

closer together. Together with our partners, we’re committed to working

on a number of initiatives to build and leverage infrastructure, new

technologies, tools, and programs to bring more people online.

One of the ways we’re working to do this is through the development of next-generation connectivity technologies like Aquila, a high-altitude platform station (HAPS) connectivity system. Though we recently decided

to shift our focus away from designing and building our own aircraft,

we’re continuing to work with the aerospace industry on technology to

make HAPS connectivity work and to advocate for improvements to spectrum

and aviation policy.

As part of our continued investment, we recently open-sourced our solar-powered aircraft design methods, named Facebook High Altitude Long Endurance (FBHALE), after presenting two papers

on the multidisciplinary optimization (MDO) based technology at the

American Institute of Aeronautics and Astronautics (AIAA) Aviation

Conference. By open-sourcing this design framework, we can help the rest

of the HAPS community optimize during the design process as well.

The need for MDO

Recent progress in battery technology, solar-cell efficiency, and

composite materials has dramatically increased the feasibility of

solar-powered perpetual flight. However, even with these improvements,

ensuring that a solar-powered aircraft can use as little power as

possible to perform in even the harshest conditions — such as the winter

solstice — still demands the highest aircraft performance. This means

maximizing aerodynamic performance (lift-to-drag ratio) and minimizing

structural mass to support maximizing energy storage capability.

However, increasing aerodynamic performance is detrimental to overall

structural weight, and vice versa. Therefore, careful trade-offs need to

be considered to ensure optimal system performance.

We developed an MDO design framework to address these challenges

early and to avoid redesigns. The design process is inherently an

optimization opportunity and, since we are looking for the best aircraft

design that can achieve our target requirements, we are utilizing an

optimization routine to both maximize objectives and satisfy

constraints.

This framework incorporates low-speed aerodynamics,

composite-structure design principles, and all the simplest physical

models that still rely on relevant physics.

Overall Logic, Disciplinary Modeling

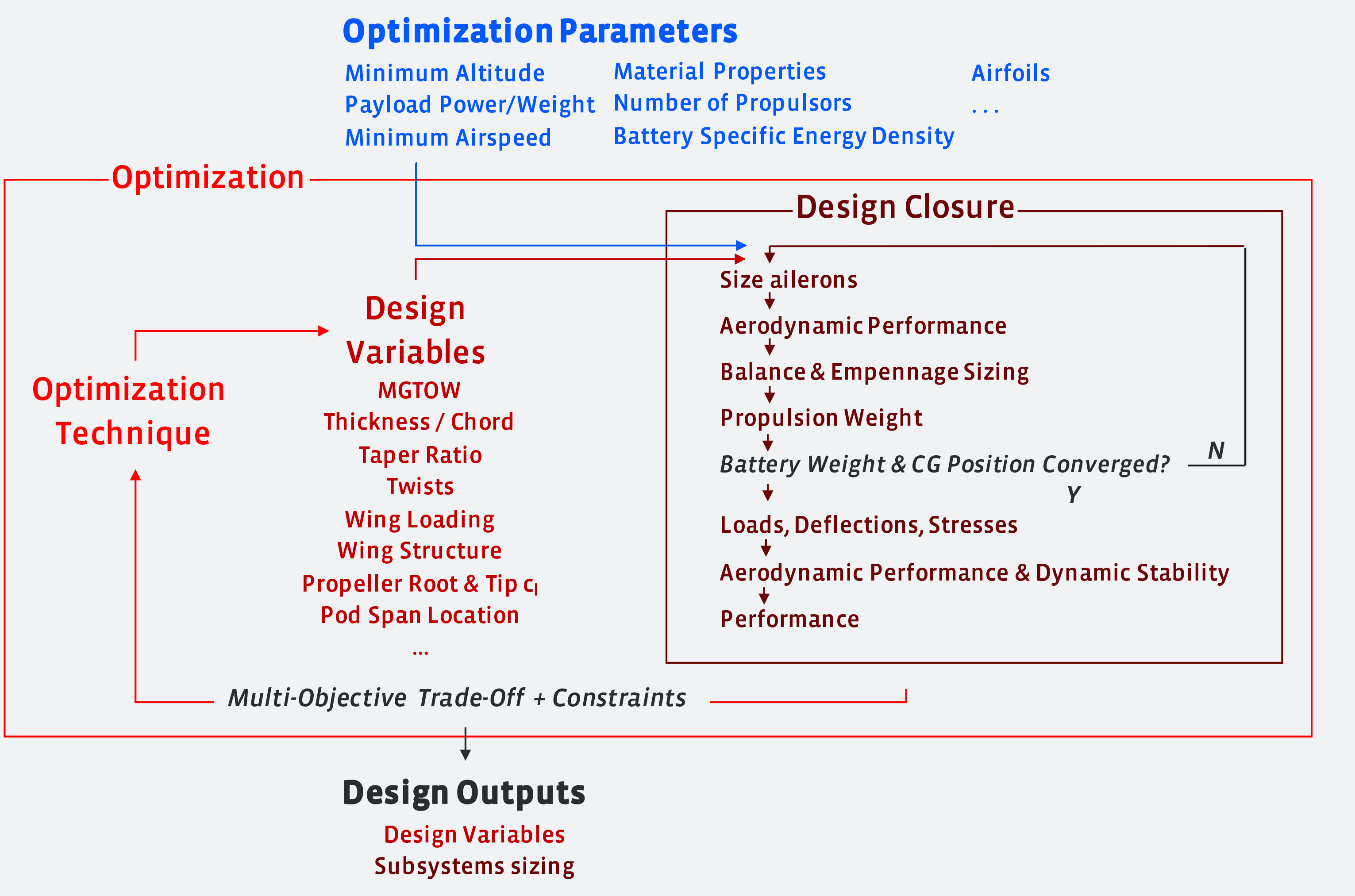

Because of the numerous variables involved in the design process of

high-altitude aircraft, this work can be challenging. In the figure

below, we have illustrated our strategy to effectively handle the number

of dimensions in this phase.

The chosen optimizer adjusts design variables to maximize the

mentioned objectives while satisfying constraints. This set of variables

is the minimum set that captures the main performance driver in each

subsystem as well as the key interdisciplinary couplings.

As part of our MDO framework, we outlined a few modeling techniques, including:

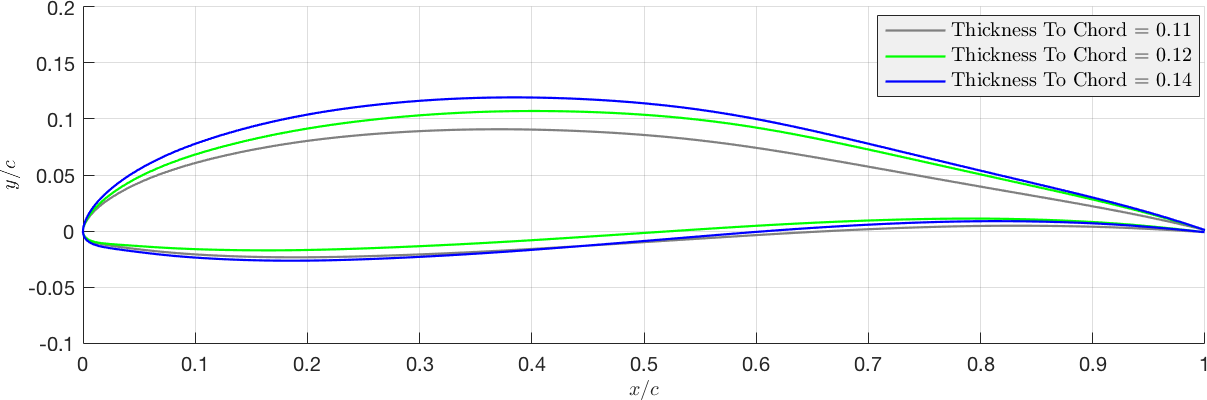

Aerodynamic Performance Modeling

At each section along the wing, the aerodynamic performance is

captured by computing the lift and drag. These quantities are dependent

on the local airfoil choice and its thickness. A thicker airfoil will

have a degraded aerodynamic performance but will allow for greater

stiffness. The thickness distribution is therefore set by the optimizer,

and a corresponding airfoil is picked from the airfoil family

illustrated below. Since lightweight wings are highly flexible, they

deflect under aerodynamic load, which modifies their shapes and the

aerodynamic forces they create. Our tool captures this important

coupling.

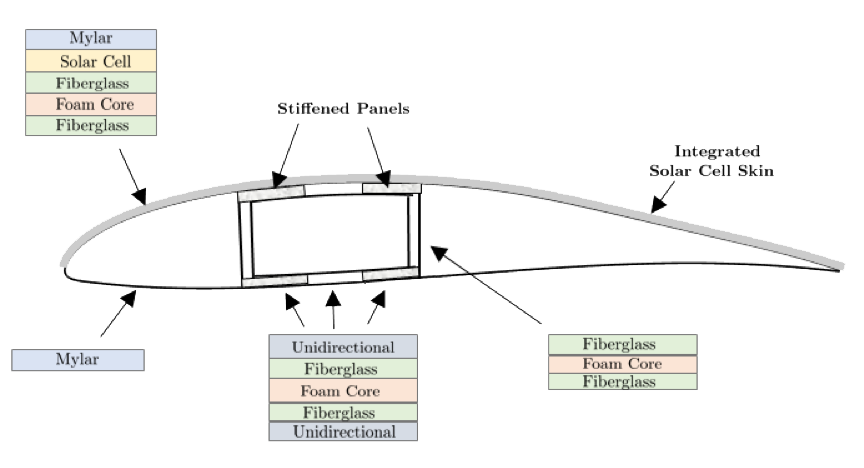

Structural Performance Modeling

The aircraft structure shown below follows a “composite box spar”

concept, with solar cells integrated into the upper surface of the wing.

Carbon fiber composite materials are employed for structural

efficiency, and the optimizer can vary key parameters such as the number

of carbon fiber plies used to adjust the stiffness of the structure.

Furthermore, we also verified that the structure would not fail during

strenuous flight conditions.

Integrated Performance calculation

The last step when evaluating a potential aircraft design is to

examine whether the aircraft can carry enough batteries to hold

sufficient energy to fly through the long nights around the winter

solstice. We also need to examine whether there is a sufficient number

of solar cells to capture power during the day to fully charge the

batteries. A typical mission would take place when there is enough sun

power to sustain flight and would include:

-

- Flying at minimum altitude until batteries are fully charged

- Once batteries are charged, if there is more sun power coming in, climbing to a higher altitude

- Gliding down to minimum altitude when the sun sets

- Using battery power, holding minimum altitude until sunrise

When simulating the winter solstice mission, we computed the amount

of power captured and stored by the aircraft, as well as the amount

consumed during the flight. This method outputs the battery state of

charge versus time, and ensures that the battery’s charge never drops

below a certain threshold.

Example Application

This design framework is particularly useful in the early design

stages of aircraft concepts because it identifies the optimal size for

an aircraft capable of flying a given latitude above or below the

equator. Additionally, key risks are identified and addressed early to

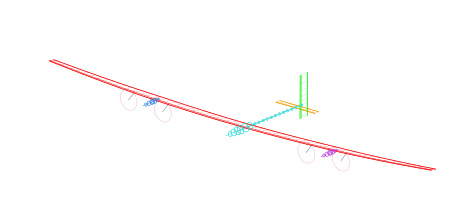

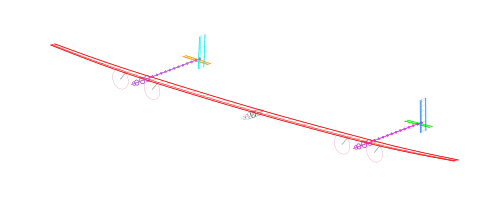

avoid redesigns. Here, we compare two configurations to illustrate how

our MDO framework can predict optimal aircraft weight and performance.

This information will feed into the configuration selection. Though in

our publications we show that we can handle flying wings, here we

investigate a single boom versus a dual boom concept:

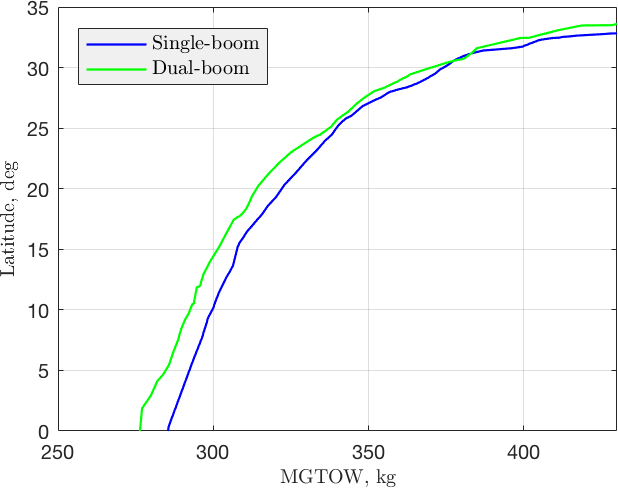

While the dual boom configuration has added mass and drag from the extra

empennage, these extra tails could potentially reduce the tendency of

the wing to start flapping and help to mitigate aeroelastic

instabilities. The output of the optimization is shown below in the form

of Pareto frontiers. At each latitude, we have illustrated the minimum

aircraft weight for each configuration:

As expected, aircraft weight goes up with latitude for both

configurations since the night gets longer, which therefore requires

larger batteries.

Future developments

HAPS connectivity remains one of the important building blocks we are

investing in to advance global connectivity, and we are excited to

continue working with the aerospace industry to optimize these

subsystems and create the highest-performing aircraft.

Since this framework is now open sourced,

aircraft designers can improve upon it and even use it for different

applications. We see potential future developments in areas such as the

control system development and integration, and more advanced power

systems and configurations. One day, this framework may even help civil

aviation authorities tackle the challenges of airworthiness

certification for these new types of solar-powered aircraft.

Join Our Engineering Community

http://www.scielo.br/scielo.php?script=sci_arttext&pid=S2175-91462016000400385

Journal of Aerospace Technology and Management

Print version ISSN 1984-9648On-line version ISSN 2175-9146

J. Aerosp. Technol. Manag. vol.8 no.4 São José dos Campos Oct./Dec. 2016

http://dx.doi.org/10.5028/jatm.v8i4.678

ORIGINAL PAPERS

Design and Manufacture of a Solar-Powered Unmanned Aerial Vehicle for Civilian Surveillance Missions

1Fundación Universitaria Los Libertadores – Facultad de Ingeniería Aeronáutica – Bogotá – Colombia.

2Universidade

de São Paulo – Escola de Engenharia de São Carlos – Departamento de

Engenharia Aeronáutica – São Carlos/SP – Brazil.

In order to promote the development of renewable energy and take

advantage of the new technologies for the benefit of sustainability,

both the design and the manufacture methodologies of an experimental

solarpowered unmanned aerial vehicle for civilian surveillance

applications are presented. Throughout the document, it is provided the

historical process around the development of the aircraft. Therefore, in

the first part, it is shown the aerodynamic design, which includes the

2-D and 3-D analyses of the wing platform using numerical and

experimental methods, the analytical design of the empennage

configuration, and the main characteristics of the performance analysis.

In addition, major systems and components that characterize the

aircraft are described, such as the photovoltaic solar cells

configuration as well as the electronics and control system into the

unmanned aerial vehicle. Lastly, the modeling for the weights

distribution of the components was carried out in a preliminary test

using CAD tools. Thus, it was obtained a suitable process for the

manufacture of the unmanned aerial vehicle, considering that the purpose

of the aircraft is to be as light and aerodynamic as possible to

accomplish the mission for which it was created.

KEYWORDS Unmanned aerial vehicle; Aerodynamic design; Performance analysis; Photovoltaic solar cells; Manufacture processes

INTRODUCTION

In the quest to find energy systems less harmful to the environment

and more efficient than the currents, the processes of design and

manufacture of a unmanned aerial vehicle (UAV) that operates with

photovoltaic solar energy are described in this paper. The application

of alternative energy sources in UAVs has established one of the broader

challenges in its design and implementation, as specified by Ramanathan et al. (2007), promoting ideas through the use of solar cells (Lubkowski et al. 2010), liquid fuel cells (Fürrutter and Meyer 2009), lithiumpolymer (LiPo) batteries (Song and James 2000),

among others. These energy sources can be a clean way to supply the

power needs of the UAVs, such as the power plant system, the telemetry

systems and the avionics. According to Herwitz et al. (2003) and MacCready et al. (1983),

the application and use of new energy management systems are joined by

the innovative and clean technology trends, which encourage the use of

new energy resources in order to reduce the impact of the pollutants as

the fossil fuels derived from the coal and petroleum.

Based on the experience of Austin (2010) and Wilkins et al. (2009),

the determining factors for the use of alternative types of energy in

UAVs are the mission and the size for which the vehicles are designed;

these factors are reflected in the weight, which is one of the most

important aspects when calculating the model. Therefore, it has been

established, according to survey data, that hybrid energy configurations

exist linking various types of energy; among the different alternatives

are: the combination of hydrogen fuel cells (LH2) with Diesel fuels or gas turbines (Nickol et al. 2007) and electric engines with solar cells (Brandt and Gilliam 1995; Romeo et al. 2007).

Consequently, one can opt for the tendency to use renewable fuels. The

efficient use of clean energy is attached to an important electronic

development. Therefore, the adaptation of systemic mathematical

algorithms from microcontrollers increases the energy efficiency and

distributes the load capacity to all electronic components, establishing

a system of energy management in the UAVs (Baoan et al. 2009).

According to data and models obtained by Nickol et al. (2007), Noth (2008) and Panagiotou et al. (2016),

some analyzes and preliminary experiments have indicated that hybrid

propulsion systems with solar energy offer excellent autonomy due to

their energy storage capacity and continuous recharge. However, they

require a large wing surface to the location of the solar panels.

Nowadays, photovoltaic cells have been the largest source of alternative

energy studied and applied. Therefore, there are references about 40

manned and unmanned experimental aircraft that take advantage of its

features, performing missions in civil and military scenarios as: the

Sky Sailor, the Helios and the Solar Impulse, that have successfully

used photovoltaic solar energy as a source of power for their operation (Nickol et al. 2007; Sun et al. 2015).

The conceptual design of the UAV was carried out taking into account

the optimal performance of the amount of harnessing solar energy

achieved by the UAVs (Cestino 2006; Youngblood et al. 1984),

which depends on the following environmental and technical factors:

seasons of the year, due to the amount of sunlight that is exposed on

the Earth’s surface; time of the day, as a result of the sunlight

intensity increase from sunrise until noon; the sun irradiance,

exploitable in some periods of the day; efficiency of the photovoltaic

cell, in which typical polycrystalline cell efficiencies are between 13

and 18%; and the surface area of the solar cells, directly proportional

to the amount of electric power supplied. Therefore, a larger wing

surface was necessary to get better results from electrical power

generation.

In this regard, a rigorous aerodynamic study was performed in order

to select the best airfoil and the best wing configuration that meet the

requirements of the aircraft. Thus, the wing was designed with a large

aspect ratio (AR) of 17, aiming to obtain the characteristics of a

sailplane wing; at the wingtip, there is a taper ratio (λ) of

0.375 for the sake of reduction of the wing tip stall effects. Thereby,

the amount of 90 cells was distributed on the upper surface of the wing

and the horizontal empennage, which are intended to power the motor and

the subsystems of the aircraft. Due to the wingspan (b) of 6 m and the maximum chord (c)

of 0.4 m, it was decided that the wings of the UAV load internally all

the structural elements and the systems for the operation, simplifying

the use of a fuselage and reducing the weight of the vehicle. Figure 1 shows the main dimensions of the wing platform of the UAV.

Figure 1 Wing dimensions in meters — UAV-SOLVENDUS full scale.

UAV DESCRIPTION

Currently, UAVs have become a very important device for the aviation

and the industrial development, presenting ideal characteristics for

recognition of inaccessible areas on missions than the traditional

aircraft. In Colombia, UAVs designed and manufactured in different

countries have been used in order to carry out different tasks in

agriculture, aerial photography, security and other areas. However, in

the last years, new academic research in UAVs have been proposed in the

Colombian aeronautical sector, mainly in partnerships with Brazilian

universities (Bravo-Mosquera et al. 2015; Herrera et al. 2014; Martínez and Cerón 2013; Parra et al. 2013).

Throughout this article, the methodological framework for the design

of a surveillance UAV integrating the use of alternative energies and

lightweight structures is presented. The UAV called SOLVENDUS (which

means “worthy of being released”) is a project that has been developed

by the Fundación Universitaria Los Libertadores, Colombia, in

cooperation with the Escola de Engenharia de São Carlos, Universidade de

São Paulo, Brazil, in the period of 2010 – 2015. The project was

divided into 3 phases.

In the first one (2010), the establishment of the mission criteria

was conducted. Therefore, a market study focused on the integration of

alternative energy in aircrafts was developed. This gave way to

consolidate the conceptual design processes of the UAV-SOLVENDUS.

At the second stage (2011 – 2012), the conceptual design of the

UAV-SOLVENDUS was initiated, taking as reference the methodological

proposals by Anderson Jr (1999), Raymer (1992) and Roskam (1997)

in relation to different configurations for fixed wing aircraft.

Thereby, the characterization of the UAV-SOLVENDUS mission in its

different phases of flight as well as the selection of the different

mechanical and electronic elements for the operation were established.

In the third phase (2013 – 2015), the complete development of the

preliminary and detail design, including manufacture, was executed. In

this regard, the aerodynamic design was performed using analytical,

numerical and experimental methods in order to validate each stage

calculated, aiming to analyze how would be the aerodynamic behavior of

the UAV performing the established mission.

The solar cells configuration on the aircraft and the arrangement

that best fits the needs of the electrical system were calculated. The

upper surface of the airfoils should be treated as a polygonal line

connected by several short line sections, as shown in Fig. 2.

In this way, it is possible to arrange the photovoltaic cells without

considerable deformations. This type of configuration can also be seen

in Cestino (2006), Gao et al. (2014) and Romeo et al. (2007).

On the other hand, new methodologies to optimize the construction of

the aircraft were implemented following the global trend by applying

manufacturing processes with composite materials. In this context, the

material selection was based on the ASTM D3039. Nowadays, flight tests

are being developed.

Figure 2 Configuration of solar panels on the selected wing airfoil.

CONCEPTUAL DESIGN

The conceptual design was based on an extensive parametric study on

the characteristics of UAVs at the same category, aiming to interpret

and analyze the main design features (geometric, aerodynamic and

performance) that make up an aircraft with solar panels (Arai et al. 2014; Marta and Gamboa 2014).

The particular requirements of the UAV-SOLVENDUS were established

taking into account the first estimation of the maximum take-off weight

(MTOW) and the desired power for flight. In this regard, most of the

UAVs that operate with solar energy use battery systems as a supplement

to its functionality. As a result, LiPo rechargeable batteries have

adapted in flight, providing a continuous-cyclical storage, which

supplies the necessary autonomy to carry out powerful flights, taking

advantage of the daylight and storing energy for night missions.

The maximum efficiency offered by the solar panels is only able to

electrically supply the electronic control and navigation systems.

However, to supply the electrical engines, auxiliary batteries charged

previously in the ground station were required. These reasons were the

base to design a lightweight aircraft in order to reduce the energy

consumption. According to Raymer (1992), the first estimation of the MTOW of an aircraft is supported by the following equation:

where: W means weight.

Analyzing the elements of the UAV-SOLVENDUS, the fuel weight is zero

because the UAV does not operate with combustion engines; on the other

hand, the crew and payload weights are irrelevant. Therefore, the MTOW

of the UAV-SOLVENDUS is characterized by the components of the empty

weight, which, by definition, are: Aircraft structure, Engines, Landing

gear and Avionics. In this respect, the weight of the aircraft depended

strictly on the manufacturing weight. Therefore, the use of materials

with a high strength/weight ratio was necessary. This relation is the

main characteristic of materials with high mechanical properties and low

densities. Thus, composite materials were used to manufacture the

experimental prototype of the UAV-SOLVENDUS, reducing the energy

consumption of the power plant and increasing the performance of the

aircraft.

From this perspective, the flight path and the mission profile

studies for the UAV-SOLVENDUS were developed considering the following

requirements and constraints:

-

Low power required (aerodynamic efficiency and low structural weight).

-

Low flight velocities.

-

Use of solar energy through photovoltaic cells.

-

Wing area sufficient for the distribution of cells.

-

Mechanical, chemical or mixed fastening for the photovoltaic cells.

-

Electric engines.

-

Integration of autonomous navigation systems.

The mission profile of the UAV-SOLVENDUS is shown in Fig. 3.

The UAV-SOLVENDUS moves at low flight regime, given the nature of its

mission and the selection of its power plant system; this should

maintain a high lift coefficient (CL) for the

fulfillment of its operation. Therefore, airfoils that provide high lift

coefficient at low speed flight were evaluated (Herrera et al. 2014).

Figure 3 Mission profile of the UAV-SOLVENDUS.

PRELIMINARY DESIGN

AERODYNAMIC STUDY

Initially, different airfoils were studied in order to determine the

appropriate selection that meets the best features for the aircraft

mission. Therefore, the best airfoil was chosen based on the “Stall”

behavior and the drag polar curve. The airfoil selected was the Eppler

212, which presents a satisfactory aerodynamic performance at low

Reynolds number. Its geometry allows attaching the solar panels.

Twodimensional computational analysis using a free-software program was

carried out, resolving the velocity field and the pressure distribution

around the airfoil. These results are suitable for maneuverability use

on the UAV-SOLVENDUS. Further information is reported in Herrera et al. (2014).

THREE-DIMENSIONAL ANALYTIC DEVELOPMENT

A free software called (Tornado® 2001) was used for the preliminary analysis of the wing, which is a vortex lattice method. Figure 4 shows the lift distribution versus

wingspan at an angle of attack equal to 4° and geometric torsion in the

wingtips. The twist angles analyzed were 0°, −2° and −4°, being

negative when the leading edge was lowered relative to the trailing

edge. Although distributions were similar, the twist angle equal to −4°

was selected aiming to prevent the wing stalling on the wingtip region.

The results show a lift force (L) of 121.61 N.

Figure 4 Comparison of lift distribution on the wing.

COMPUTATIONAL ANALYSIS

For this stage, the ANSYS®-FLUENT code (ANSYS® 2011)

was used in the modeling of airflow over the wing (scale 1:3). The

computational domain used was large enough to avoid the fluid

restriction in the simulations. It was discretized in both space and

time through an appropriate mesh, where the Navier-Stokes equations were

solved. In this regard, the distance to the nearest wall was set at 1 ×

10−4, resulting in a Y+ ≈ 5. The number of elements generated was 3.8 × 106, using an unstructured mesh (tetrahedral). The mesh generated for the wing model is shown in Fig. 5.

Figure 5 Unstructured mesh and grid details for the wing simulation.

All the simulations were performed with the International Standard

Atmosphere (ISA) parameters at the atmospheric conditions of São Carlos,

São Paulo, Brazil, where the experiments were executed. The variation

of the angle of attack was from −4° to 18° at a Reynolds number of 2.05 ×

105. The Shear Stress Transport (SST) turbulence model was

chosen by its most common applications in the aerospace field related

with limited flows by walls and simulations at low Reynolds numbers (ANSYS® 2011; Kontogiannis and Ekaterinaris 2013).

In addition to the good numerical approximations of the model’s

aerodynamic qualities compared with the experiments, the Computational

Fluid Dynamics (CFD) simulations allowed to understand the behavior of

the streamlines in each condition. In this connection, Figs. 6a and 6b

show the streamlines at angles of attack equal to 4° and 10°,

respectively. As can be observed, at 10° there is a cross flow and fluid

detachment compared with the simulations at 4°.

Figure 6 Streamlines at (a) 4°; (b) 10°.

EXPERIMENTAL AERODYNAMIC MODEL

Taking into account the dimensions of the test section of the wind tunnel (LAE, Fig. 7) (1.3 × 1.7 × 3 m) located at the Escola de Engenharia de São Carlos, Universidade de São Paulo (Catalano 2001), the wing model was built at a 1:3 scale. The experiments were executed at 25 m∙s–1.

For the manufacture of the model, the ribs were made in medium density

fiberboard (MDF), with thickness of 6.3 mm, the coating was made of

polyvinyl chloride (PVC), with thickness of 0.5 mm, and plastic tubes

were built at 25% chord on the scale for the pressure taps. The

experimental model used was a semi-span wing of 1 m, 0.05 m tip chord

and 0.13 m in root chord, as well as taper ratio of 0.375, having a

constant section of 0.60 m and a tip section of 0.40 m.

Figure 7 Wing model at the wing tunnel

ACQUISITION AND ANALYSIS RESULTS

Figure 8 presents the comparison of the numerical results obtained by the ANSYS®-FLUENT code with the experimental data. In Fig. 8a,

the numerical and experimental results at low angles of attack were

very close, being obtained a numerical lift coefficient at zero angle of

attack equal to 0.22 (for the experimental case, the angle was equal to

0.2). However, a divergence in the result begins to exist from 8°. From

an angle of attack of 10°, the inclination of the curve changes and the

growth rate of the lift coefficient decreases. As could be observed in Fig. 6b,

the presence of cross flow suggests that the wing is beginning to

stall. Furthermore, an excellent approxi mation of the experimental and

numerical results regarding the drag coefficient (CD) was obtained, as can be seen in Fig. 8b, where the drag coefficient at zero angle of attack was practically set at 0.03. In Fig. 8c,

both experimental and computational moment coefficients around the

aerodynamic center were negative, confirming that the wing has a

tendency to contribute to the stability of the aircraft. Figure 8d shows the drag polar curve, in which it was observed that the maximum aerodynamic efficiency (L/D)

was set at 4° for the experimental results and at 5° for the numerical

ones. Therefore, this angle of incidence was selected to optimize the

mission profile, due to the reduction of the energy consumption.

Figure 8 Aerodynamic curves — wing model. Scale 1:3.

Finally, in Table 1,

the principal results of the total analysis of the wing platform are

summarized. As a conclusion, the analytic, numerical and experimental

results were well-developed, since the results are close, giving the

knowledge of the aerodynamic behavior of the UAV-SOLVENDUS in the

established mission.

Table 1 Comparison of aerodynamic coefficients.

| Aerodynamic parameters | Experimental | Numerical | Analytical |

|---|---|---|---|

| Maximum CL | 1.11 | 1.18 | 1.35 |

| α for CLmax | 15° | 15° | 10° |

| CD at zero α | 0.025 | 0.025 | 0.02 |

| δCMlδα | -0.0072 | -0.012 | -0.099 |

| Maximum (L/D) | 22.23 | 24.88 | 34.34 |

| a for (L/D)max | 4° | 5° | 4° |

EMPENNAGE DESIGN

After meeting the aerodynamic and geometric characteristics of the

wing platform, the empennage development was carried out in order to

study the stability behavior of the UAV-SOLVENDUS. In this regard, 3

configurations were examined (conventional, v-tail, and twin-tail); the

Twin-tail was selected and connected to the wing via booms. For the

horizontal stabilizer, the initial surface area was calculated

geometrically from the design conceptions. Therefore, the dimensions of

the solar panels were considered, i.e. the chord of the

horizontal stabilizer was limited by the size of the solar cells,

regardless of the relative position that was assumed (long-wide). The

dimensions of the solar cells are: 14.6 × 24.8 cm. Thus, the horizontal

stabilizer surface (SH) was 0.405 m2. The airfoil

chosen was a NACA 0012, determined by static-dynamic stability and

control criteria. For the benefit of simplicity in manufacture, the

vertical stabilizer uses a NACA 0009, and its surface area is 0.23 m2.

According to the parameters shown in Fig. 9,

a conceptual analysis of the longitudinal static stability was carried

out, aiming to validate the configuration of the empennage design, where

ACw is the aerodynamic center of the wing, ACt

is the aerodynamic center of the tail and GC is the aircraft gravity

center. The longitudinal stability contribution of the wing, the

empennage, and the full configuration were calculated in order to

maintain the moment coefficient derivative (∂Cm/∂α < 0) for the UAV. Figure 10 shows the moment coefficient at the center of gravity versus

the angle of attack of each mentioned surfaces. As a result, the trim

angle for the UAV-SOLVENDUS is set at 4°. The static margin (ST) for

this case was at 17% of the mean aerodynamic chord (MAC), and the

neutral point (NP) was at 47% of the MAC. The 3 views of the final

prototype of the UAV-SOLVENDUS with its principal dimensions are shown

in Fig. 11.

Figure 9 Static margin representation.

Figure 10 Stability contribution of the aerodynamic surfaces.

Figure 11 Dimensions of the final design of the UAV-SOLVENDUSin meters.

AIRCRAFT PERFORMANCE EVALUATION

Initially, the thrust required for the UAV-SOLVENDUS was estimated regarding the cruise velocity equal to 25 m∙s–1 and the MTOW of 12 kg, determined in the conceptual design phase. Then:

For this case, the drag coefficient was analytically calculated, taking

into account the form factor, the wet area, and the skin friction

coefficient of the aerodynamic surfaces, in order to calculate the

parasite drag and the characteristics of the wing configuration for the

induced drag. As a result, the analytic drag polar equation for the

UAV-SOLVENDUS was:

In this regard, the first estimation of the thrust required for this condition was TR = 6.75 N. As a result, it was studied the thrust generated by different propellers for the engine Axi2820/12 (Axi Model Motors, 2015)

in order to establish the differences or similarities in relation to

the necessary force to move the aircraft in flight under the

restrictions already mentioned. Thus, two propellers with 11 × 8″ were

selected, providing a total thrust available T = 77.91 N and an efficiency ηp = 80.2%. To obtain the capacity value of the electrical work generated by the engine Axi2820/12 (Axi Model Motors 2015) and the power required (PR) for the aircraft, the following relations were established:

where: P is the electrical power; ρ is the density; S is the wing surface; the values for electric current (I) vary between 15 to 25 A; the motor resistance (R) is set at 0.059 ω.

The engine manufacturer (Axi Model Motors 2015)

assumed these values as ideal. Therefore, these were selected as the

initial parameters for calculating the engine performance. In Fig. 12, the thrust and power required by the UAV-SOLVENDUS are shown at different velocities. As can be observed, for the (L/Dmax),

the thrust and power required presented the lower values available,

and, for the cruise velocity, the thrust and power required for the

UAV-SOLVENDUS were 15 N and 400 W, respectively.

Figure 12 Thrust and power required by the UAV-SOLVENDUS.

PHOTOVOLTAIC SOLAR CELLS CONFIGURATION

The photovoltaic solar system has the purpose of supplying electrical

energy to the internal systems of the aircraft. The motors are the

components that present higher energy consumption. A motor Axi2820/12

was selected, which has a maximum capacity of 500 W and works with LiPo

batteries of 3 and 4 cells. In this way, each motor operates with

voltages ranging between 11.1 and 14.8 V, and the current varies between

45 and 30 A. The other elements that consume power are the avionics and

servos, which operate at 5 and 6 V with currents of 4.5 A.

In order to determine the best arrangement according to the needs of

the avionics and servos systems, it was necessary to carry out a

characterization of each solar cell under real operating conditions. Figure 13

shows the behavior of solar radiation against time during the course of

the tests. This reflected the drop in the level of solar radiation with

dusk, confirming that the best time of the day for test flights is

between 13:00 and 15:00 pm (Arai et al. 2014; Chang et al. 2014). Table 2

shows the environmental test conditions. In order to consider the

variation of the solar radiation along the day, voltage and current were

measured at different times of the day. In this manner, the voltage of

the cells (V-cell) changed from 9 to 10 V (Fig. 14a), and the current (I-cell) changed with a rate of 0.1273 mA/(W∙m–2) (Fig. 14b).

Figure 13 Radiation levels versus time.

Table 2 Environmental test conditions of the photovoltaic solar panels.

| Test | Environmental temperature (°C) | Time of the day (24 h) | Weather |

|---|---|---|---|

| 1 | 19 - 20 | 14:05 | Sunny |

| 2 | 19 - 20 | 14:10 | Sunny |

| 3 | 19 - 20 | 14:15 | Sunny |

| 4 | 19 - 20 | 14:20 | Sunny |

| 5 | 19 - 20 | 14:25 | Sunny |

| 6 | 19 - 20 | 14:30 | Sunny |

| 7 | 19 - 20 | 14:35 | Sunny |

| 8 | 18 - 19 | 14:40 pm | Partly cloudy |

| 9 | 18 - 19 | 14:45 pm | Partly cloudy |

| 10 | 18 - 19 | 14:50 pm | Partly cloudy |

Figure 14 Cells voltages (a) e current (b) under operating conditions (temperature between 19 and 20 °C).

Regarding avionics and servos requirements, a hybrid configuration

was implemented, which has pairs of cells connected in series, in order

to produce higher voltages (Fig. 15a), and all the pairs connected in parallel with the aim of increasing the current of the circuit (Fig. 15b).

The cells were placed over the entire surface of the wing and the

horizontal stabilizer, consisting of 45 pairs of cells that provide

4,500 mA with voltage ranging between 14 and 20 V. Figure 16 shows the scheme of the final configuration of the solar panel system.

Figure 15 Cells connected (a) series; (b) hybrid array.

Figure 16 Scheme of the fi nal confi guration of the solar panels.

On the other hand, in order to determine the efficiency of the cells,

it was necessary to know their voltage-current curve characteristics.

This curve is provided by the manufacturer PowerFilm RC7.2-75 PSA (PowerFilm Solar® 2006) and is shown in Fig. 17. The points A and B

represent certain conditions given by the load, resistance and voltage.

Bearing in mind that the temperature of the cells do not match the

ambient temperature, it was necessary to estimate the variation of their

temperature in relation to the environmental temperature. According to Mattos et al. (2013) and Skoplaki and Palyvos (2009),

the efficiency of the cells at ambient temperature, between 19 and 20

°C, oscillates in a range from 4 to 7%. As there is variability in the

electrical properties of each cell, the selection of the cells

arrangement was carried out taking into account that the cells connected

in pairs have to provide similar efficiencies in the hybrid

configuration. The pairs of cells for the hybrid configuration were made

with those of similar efficiencies.

Figure 17 100% Sun — standard test conditions, AM 1.5. Cell effi ciency.

ELECTRONICS AND CONTROL SYSTEMS

The internal structure of the UAV requires electronic devices that

allow identifying and establishing the attitude and position. For the

attitude of the UAV-SOLVENDUS, environmental data are collected through a

set of devices (Type COST, Commercial off -the-shelf), as inertial

measurement unit (IMU), which perform the angular speeds (P, Q, and R) measurements in the movements of pitch, roll and yaw — with its respective Moment (Ma) in addition to the measurement of acceleration in the x, y, and z axes using accelerometers and gyroscopes (Ac)

integrated with a micro-controller. The variables that are acquired

from these sensors are subjected to an estimation process called Kalman

filter, whereby it is possible to determine the attitude of the UAV.

In order to position the UAV and enable the navigation, a global

position system (GPS) device was used. The altitude on the take-off and

landing stages was determined by a sonar and an altimeter. High

altitudes (above 2,000 m) were measured with a barometric altimeter. An

additional sensor is the magnetometer or digital compass, which revealed

the azimuth of the UAV. The scheme of these devices can be observed in Fig. 18.

Considering that the power offered by the solar panels are only able to

supply electrically the electronic control and aircraft navigation

systems, the supply of the propulsion system must be performed by a set

of auxiliary batteries (2S – 3S LiPo batteries), preloaded on the ground

station. The electricity produced by the solar panels goes directly to

the batteries that store and distribute energy to all the electronic

components connected to this system. Batteries and panels are connected

to a 12-V 2.2-A step-down voltage regulator D24V22F12 in order to keep a

constant voltage of 12 V. The energy distribution of the electrical

system is shown in Fig. 19.

Figure 18 Scheme of the navigation system.

Figure 19 Energy distribution.

MANUFACTURE PROCESS

For structural design of the aircraft, it is important to consider

the materials used for manufacturing. In this regard, for this project,

the properties of the composite materials were studied, and it was

decided to use carbon fiber. Depending on the component and its

complexity, the methodology of using the materials and the assembly

procedures can change; since a large part of the components were made of

composite materials, manufacturing methods were defi ned, e.g. manual contact molding or vacuum packing.

Methodologies of vacuum packing were selected, whose advantages were:

-

Allow the realization of parts in small and medium series, without restriction of shapes and sizes.

-

Uniform distribution of the resin and reduction of the air inclusions, resulting in good mechanical properties.

-

Good surface appearance of both sides.

A suitable process for the manufacture of the parts was carried out;

it should be noted that the inputs must be placed in a correct and

precise order, aiming to obtain a suitable finishing. Figure 20

shows the correct order of the inputs placed. Before to start the

construction, the detail design of each part of the main surfaces was

performed using CAD tools. With these designs, it was possible to adjust

the distribution of the structural parts mainly in the wings and the

empennage. Figure 21

shows the distribution of the ribs and stringers in the wing and the

empennage. Jigs were used in order to control the location of the

components during this process. Besides serving for correct alignment,

jigs fulfil the function of temporary supports during assembly model.

Figure 21 Distribution of ribs and stringers on the wing and empennage.

After mounting the jigs, the ribs (which were formed by a core of

light wood, 1.5 mm thick, and 2 layers of carbon fiber, 0.7 mm thick,

forming a “sandwich”, Fig. 22,

with a thickness of 2.2 mm) were located on the jigs and joined to the

beam. At the end of the process, 3 sections of 2 m each were built for

the wing. The 3 wing sections were joined with screws for an easy

assembly and disassembly. The fuselage manufacturing was made in

sections. In the first instance, the fuselage CAD model was printed in a

3-D printer machine; this impression served to make the molds for

manufacturing in composite material. Figure 23

shows the molds and the final manufacture of the fuselage. On the other

hand, the UAV skin manufacture was performed in 6 sections,

distributing inputs in the correct order as pointed in Fig. 20. As a result, each layer presented 2.20 × 0.40 m and weight of 173.4 g. Figure 24 shows the aircraft skin manufacture processes.

Figure 22 Wing rib detail.

Figure 23 Fuselage manufacture.

Figure 24 Skin manufacture.

Each rib of the aircraft was check to ensure adherence of the skin

with the wing structure and the empennage. During this process, the ribs

and the main beam of the UAV were reinforced. The adhesion of the skin

with the ribs of the wings was carried out with resin by the stringers

designed; the union covered the leading edge and part of the main beam. Figure 25

shows the joint between the skin and ribs. Finally, tail booms were

built with an “I” profile with carbon fiber and light wood cored, which

were joined to the vertical stabilizers with 6 screws on each side. Figure 26 shows the final assembly of the UAV-SOLVENDUS ready to flight.

Figure 25 Joint between skin and ribs.

Figure 26 UAV-SOLVENDUS experimental prototype.

CONCLUSIONS

The first prototype of a light, solar-powered UAV for civilian

surveillance missions was designed and successfully constructed, being

one of the first projects that are registered in Colombia as viable due

to the integration of independent complex systems. It has expanded the

discussion of the development of unmanned systems designs with the aim

of performing missions that could not be made with traditional aircraft.

The results obtained with analytical, computational, and experimental

methods have served to enrich the research exercise around the design of

the UAV-SOLVENDUS. Therefore, it was possible to analyze and validate

the main findings during the design process, which are summarized as

follows:

-

CFD tools were used in order to study and compare the experiments performed on the wing model. The aerodynamic efficiency (L/D)

obtained in the wing design method reveals that it is maximum at 4°.

Therefore, this angle of attack is recommended for better aerodynamic

efficiency at cruise flight for the UAV. -

The combination of improvements proposed by the authors, as the

increase in the wingspan and the wing surface, lead to a greater range

and endurance of the aircraft. Therefore, the UAV-SOLVENDUS is a more

economical and eco-friendly aircraft, compared with the other UAVs

destined to perform similar missions. -

For this first prototype, an experimental study for the solar

panel system characterization was executed, with the aim of analyzing

the voltage, current, and power of UAV requirements according to

different levels of radiation in real operating conditions. As a result,

the most appropriate cells arrangement (hybrid) was chosen, in order to

supply the power requirements for the avionics equipment, since the

propulsion system must be energized with auxiliary batteries. -

The performance of the current solar power system is under

evaluation. Until now, its behavior has been acceptable to supply the

power necessary to the onboarding system, even though it has not been

wholly satisfactory to supply energy to the propulsion system, and

electrical batteries are still necessary. -

The manufacture process was developed based on ASTM D3039. The

features offered by the carbon fiber were appropriate for the model;

factors such as weight, strength, and behavior in environmental

conditions were remarkably outstanding in the performed test.

Finally, through this investigation, it was possible to demonstrate

the benefits of using renewable energies in the aeronautical engineering

field, allowing to know new alternatives to the use of photovoltaic

solar panels on aircraft models that seek to optimize the fuel

consumption, keeping high values of endurance and range.

ACKNOWLEDGEMENTS

The authors express their gratitude to the Fundación Universitaria

Los Libertadores, for the financial support, as well as to its Oficina

de Relaciones Interinstitucionales (ORI), for the support to the Student

Exchange Program. The Grupo de Investigación en Ciencias Aeroespaciales

(GICA), for the cooperation and devotion on the development of this

project. Prof.Fernando Martini Catalano, for the support in the

preparation of the experiments at the Laboratório de Aerodinâmica, Dep.

Engenharia Aeronáutica, Escola de Engenharia de São Carlos, Universidade

de São Paulo.

AUTHOR’S CONTRIBUTION

Betancourth NJP, Villamarin JEP and

Rios JJV conceived the idea and co-wrote the text. Cerón-Muñoz HD headed

the current project and co-wrote the text. Bravo-Mosquera PD, aided on

the calculations, prepared the figures and co-wrote the main text. All

authors discussed the results and commented on the manuscript.

REFERENCES

Anderson Jr JD (1999) Aircraft performance and design. Boston: WCB/ McGraw-Hill.

[ Links ]

ANSYS® (2011) ANSYS FLUENT theory guide. Canonsburg: ANSYS, Inc.

[ Links ]

Arai

N, Harasani W, Hiraoka K (2014) Conceptual design of solar UAV for long

endurance. St. Petersburg: International Council of Aeronautical

Science.

[ Links ]

Austin R (2010) Unmanned aircraft systems: UAVS design, development and deployment. Chichester: Wiley.

[ Links ]

Axi Model Motors (2015) Axi2820/12 gold line, data sheet, technical specification, catalogue products; [accessed 2016 Feb 24]. https://www.modelmotors.cz/

[ Links ]

Baoan

L, Zhihua L, Xinjun L (2009) Research of UAV engine fault prediction

based on particle filter. Proceedings of the 9th International

Conference on Electronic Measurement and Instruments; Beijing, China.

[ Links ]

Brandt

SA, Gilliam FT (1995) Design analysis methodology for solarpowered

aircraft. J Aircraft 32(4):703-709. doi: 10.2514/3.46780

[ Links ]

Bravo-Mosquera

P, Uribe A, Catalano F, Abdalla A (2015) Parametric conceptual design

of a UAV for superficial volcano monitoring. Proceedings of the 23rd

ABCM International Congress of Mechanical Engineering; Rio de Janeiro,

Brazil.

[ Links ]

Catalano

F (2001) The new closed circuit wind tunnel of the aircraft laboratory

of University of São Paulo. Proceedings of the 16th Brazilian Congress

of Mechanical Engineering; Uberlândia, Brazil.

[ Links ]

Cestino

E (2006) Design of solar high altitude long endurance aircraft for

multi payload and operations. Aero Sci Tech 10(6):541-550. doi:

10.1016/j.ast.2006.06.001

[ Links ]

Chang

M, Zhou Z, Wang R, Xu X (2014) A general design methodology for

year-sound solar-powered stratospheric UAVs from low to middle

latitudes. St. Petersburg: International Council of Aeronautical

Science.

[ Links ]

Fürrutter

MK, Meyer J (2009) Small fuel cell powering an unmanned aerial vehicle.

Proceedings of the AFRICON 2009; Naibori, Kenia.

[ Links ]

Gao X,

Hou Z, Guo Z, Chen X (2014) Design and performance test of a twin

fuselage configuration solar-powered UAV. St. Petersburg: International

Council of Aeronautical Science.

[ Links ]

Herrera

J, Silva N, Tellez C, Cerón H, Pedraza N (2014) Análisis aerodinámico

computacional y experimental para el ala de un mini vehículo aéreo no

tripulado (VANT). Proceedings of the 8th Congresso Nacional de

Engenharia Mecânica; Uberlândia, Brazil.

[ Links ]

Herwitz

S, Dunagan S, Sullivan D, Higgins R, Johnson L, Zheng J, Aoyagi M

(2003) Solar-powered UAV mission for agricultural decision support.

Proceedings of the International Geoscience and Remote Sensing

Symposium; Moffett Field, USA.

[ Links ]

Kontogiannis

G, Ekaterinaris J (2013) Design, performance evaluation and

optimization of a UAV. Aero Sci Tech 29(1):339-350. doi:

10.1016/j.ast.2013.04.005

[ Links ]

Lubkowski

S, Jones B, Rojas E, Morris D (2010) Trade-off analysis of regenerative

power source for long duration loitering Airship. Proceedings of the

Systems and Information Engineering Design Symposium (SIEDS-IEEE);

Charlottesville, USA.

[ Links ]

MacCready

PB, Lissaman PBS, Morgan WR, Burke JD (1983) Sun-powered aircraft

designs. J Aircraft 20(6):487-493. doi: 10.2514/3.44898

[ Links ]

Marta

A, Gamboa P (2014) Long endurance electric UAV for civilian surveillance

missions. St. Petersburg: International Council of Aeronautical

Science.

[ Links ]

Martínez

P, Cerón H (2013) Análise computacional das características

aerodinâmicas de um VANT em configuração box-wing. Proceedings of the

6th Congreso Internacional de Ingeniería Mecánica (CIMM); Barranquilla,

Colombia.

[ Links ]

Mattos

BS, Secco NR, Salles EF (2013) Optimal design of a high-altitude

solar-powered unmanned airplane. J Aerosp Technol Manag 5(3):349-361.

doi: 10.5028/jatm.v5i3.223

[ Links ]

Nickol

L, Guynn M, Kohout L, Ozoroski T (2007) High altitude long endurance

air vehicle analysis of alternatives and technology requirements

development. Proceedings of the 45th Aerospace Sciences Meeting and

Exhibit; Reno, USA.

[ Links ]

Noth A (2008) Design of solar powered airplanes for continuous flight (PhD thesis). Zürich: ETH Zürich.

[ Links ]

Panagiotou

P, Tsavlidis I, Yakinthos K (2016) Conceptual design of a hybrid solar

MALE UAV. Aero Sci Tech 53:207-219. doi: 10.1016.ast.2016.03.023

[ Links ]

Parra

J, Cerón H, Gómez A (2013) Pruebas aerodinámicas experimentales de

aeronave con alta relación de aspecto a bajos Reynolds. Proceedings of

the 6th Congreso Internacional de Ingeniería Mecánica (CIMM);

Barranquilla, Colombia.

[ Links ]

PowerFilm Solar® (2006) RC7.2-75 PSAF. Datasheet. Catalogue products; [accessed 2016 May 1]. http://www.powerfilmsolar.com/

[ Links ]

Ramanathan

V, Ramana MV, Roberts G, Kim D, Corrigan C, Chung C, Winker D (2007)

Warming trends in Asia amplified by brown cloud solar absorption. Nature

448:575-578. doi: 10.1038/nature06019

[ Links ]

Raymer DP (1992) Aircraft design: a conceptual approach. Washington: American Institute of Aeronautics and Astronautics.

[ Links ]

Romeo

G, Frulla G, Cestino E (2007) Design of a high-altitude long-endurance

solar-powered unmanned air vehicle for multi-payload and operations.

Proc IME G J Aero Eng 221(2):199-216. doi: 10.1243/09544100JAERO119

[ Links ]

Roskam J (1997) Airplane aerodynamics and performance. Lawrence: DAR Corporation.

[ Links ]

Skoplaki

E, Palyvos JA (2009) On the temperature dependence of photovoltaic

module electrical performance: a review of efficiency/power

correlations. Sol Energ 83(5):614-624.

[ Links ]

Song

L, Evans JW (2000) Electrochemical‐thermal model of lithium polymer

batteries. J Electrochem Soc 147(6):2086-2095. doi: 10.1149/1.1393490

[ Links ]

Sun K,

Zhu M, Wang L, Liu H (2015) Analysis of the hybrid power system for

high-altitude unmanned aircraft. Advances in Materials Science and

Engineering 2015(2015):Article ID 380708.

[ Links ]

Tornado® (2001) A vortex lattice method implemented in MATLAB; [accessed 2016 May 4]. http://tornado.redhammer.se/

[ Links ]

Wilkins

G, Fourie D, Meyer J (2009) Critical design parameters for a low

altitude long endurance solar powered UAV. Proceedings of the AFRICON

2009; Naibori, Kenia.

[ Links ]

Youngblood

JW, Talay TA, Pegg RJ (1984) Design of long-endurance unmanned

airplanes incorporating solar and fuel cell propulsion. Proceedings of

the 20th Joint Propulsion Conference; Cincinnati, USA.

[ Links ]

Received:

May 05, 2016; Accepted:

July 04, 2016

This

This

is an Open Access article distributed under the terms of the Creative

Commons Attribution License, which permits unrestricted use,

distribution, and reproduction in any medium, provided the original work

is properly cited.

CEP: 12 228-901, tel (55) 12 99162 5609

secretary@jatm.com.br